PFEIFFER Biegetechnik: More than just a promise

Where stretch bending is concerned, PFEIFFER Biegetechnik has proven to be the competent partner at your side for over 50 years

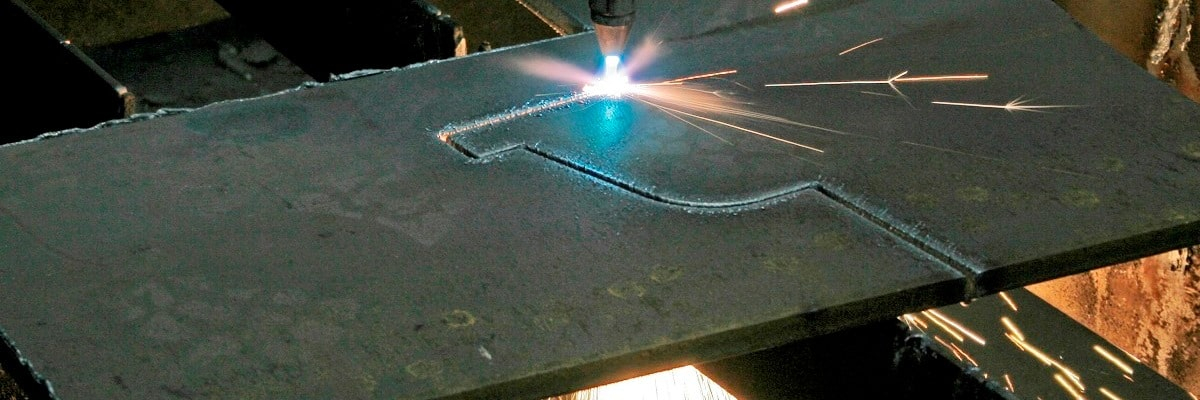

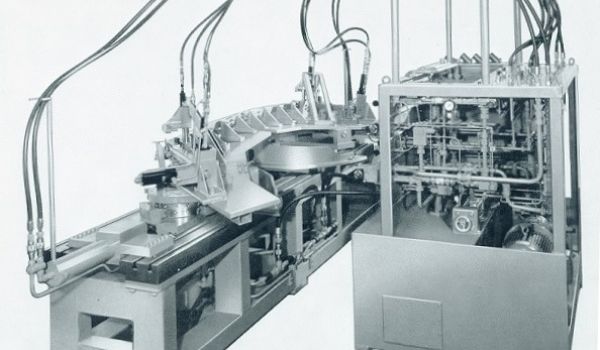

Our company’s headquarters located in Finnentrop and situated within the industrial and economic region of South-Westphalia, is where we produce stretch bending machines on a production area covering approx. 2,500 m². Supplementary to a combination of manufacturing processing steps such as sawing and drilling, the production of highly complex bent 3D components is also possible.

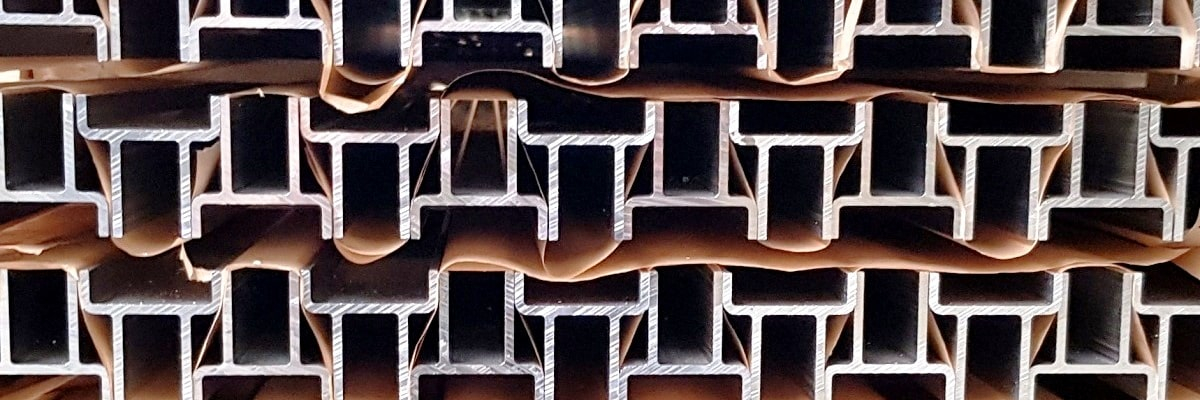

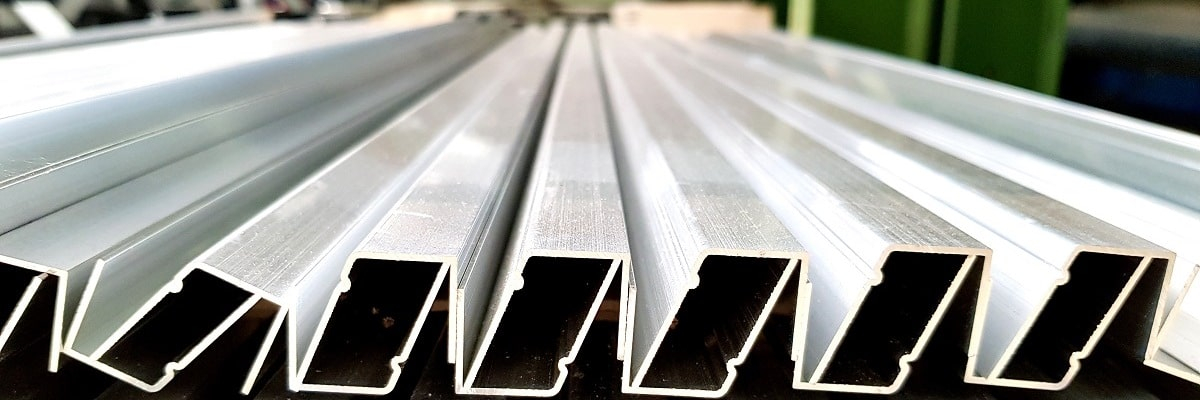

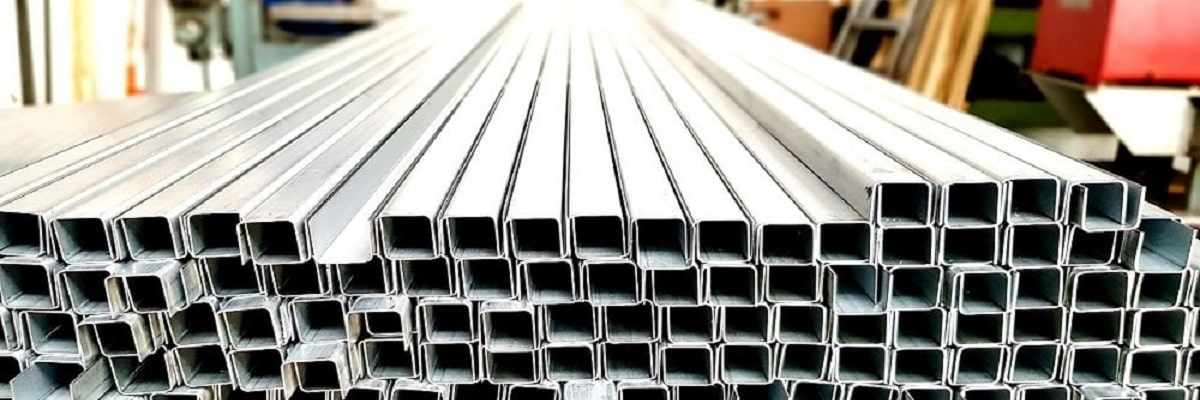

The materials employed range from plain steel e.g. 1.1730 through to high-strength steel materials such as SPFC1180Y or stainless steels like 1.14305. Where aluminium materials are concerned, alloys between 2000 and 6000 are normally used and the 7000 group for high-strength applications

Our range of machines with nominal forces of generally 10-750 kN and 16 controlled axles offer almost unlimited possibilities in solving your bending requirements and in particular, the procedural engineering benefits of stretch bending such as

- very short cycle times

- avoidance of wave formations on the inside of the bend

- 3-dimensional alignment of the component as well as

- highest grade of accuracy

provides you with the prerequisites for an optimal production design.

With our experience, our know-how and our absolute commitment in what we undertake, our mission is to meet and fulfil your requirements.

AN OVERVIEW OF OUR SERVICES

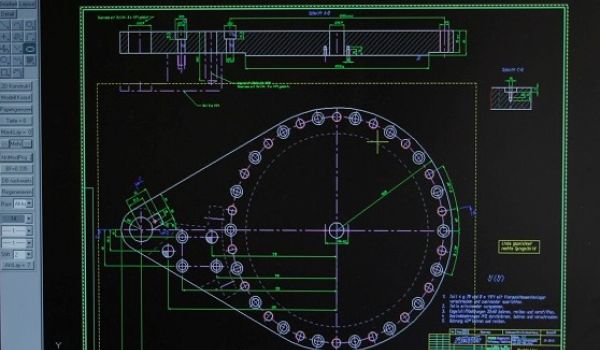

In the field of component development, our range of services extend from processing analysis through to the prototype production and the pilot production of bending tool prototypes up to the manufacture of small series.

Our machines offer:

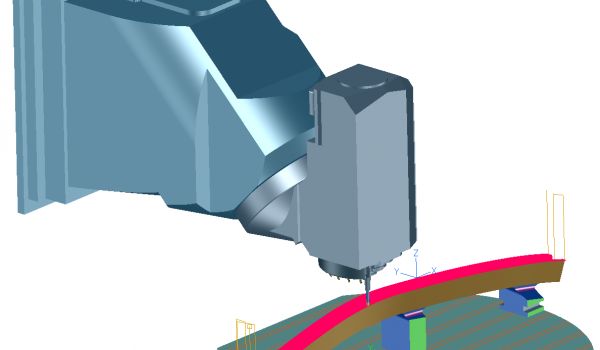

- A production up to the highest grade of accuracy is achieved by the use of 16 directly controlled axles. The optional use of additional controlled axes to the stretching tool can give further assistance to possible complex stretching requirements.

- A control panel with an intuitive interface allowing for the stretching programme to adjust to the bending properties of the varying raw material batches without the knowledge of CNC or computer programming being needed.

- The integration of further machining steps e.g. sawing and drilling within the bending cycle.

- A 3-dimensional component alignment (3 basic axles plus an additional torsion).

- The operation of various tools in alternation

No matter which material, be it aluminium, high-strength steel or any other bendable material, with nominal forces normally ranging from between 10 to 750 kN, we can meet your bending requirements.

OUR REFERENCES

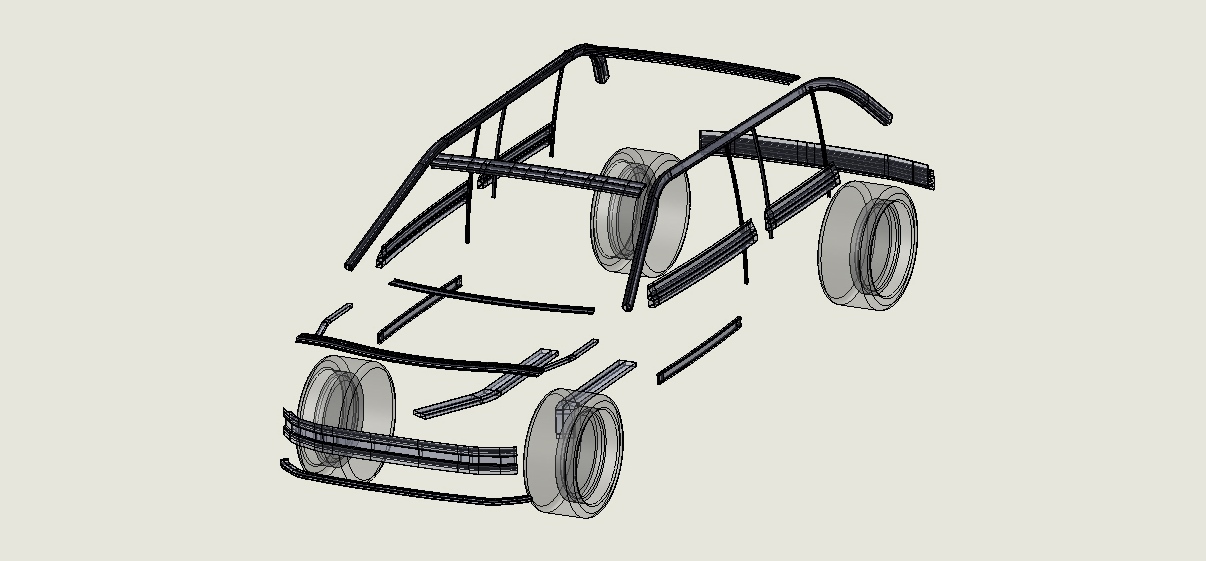

Our technical bending solutions are employed by international players within the automobile industry such as Mercedes Benz, AMG Mercedes, Porsche, Audi or the Volkswagen Group.

Application possibilities

Soft top roof systems for:

- manual roof systems

- automatically operated rooftop systems

- hard or soft top

Special applications

Further fields of application where we can apply our experience are as follows:

- cover strips or handrail profiles for escalators

- structural components for railway vehicles

- frame components for the safety cabins of working/processing machines

HISTORY

The history of PFEIFFER Biegetechnik

CONTACT

We look forward to hearing from you

KOHLHAGE E-Tech GmbH

Industriestraße 53

57413 Finnentrop

Telefon +49 2394 619-0

Fax +49 2394 619-90

E-Mail: info(at)Kohlhage.de